As a postdoc, Monika Choudhary applies computing models to real experimental data at the ALS, work that uses her extensive computer science knowledge and experience. Read more about the path that led her to the ALS and the people she’s met along the way. Read more »

Ringleaders & Postdocs

Matthew Marcus, STXM Beamline Scientist

From the microscope at work to the telescope at home, Matthew Marcus is captivated by space sciences. In this interview, he shares some of the findings from Beamline 5.3.2.2 as well as stories from his long career in x-ray science. Read more »

Quentin Williams, 2024 Users’ Executive Committee Chair

Living in the Santa Cruz mountains, Quentin Williams spends a lot of time tending to projects on the Earth’s surface, but his professional interests lie thousands of kilometers below. His geosciences research led him to become a long-time user of the ALS, where he is serving as the UEC chair for 2024. Learn more about his work and hear his advice for other ALS users. Read more »

Dahlia An, User Safety Specialist

Dahlia An is new to the ALS but not to Berkeley Lab. Read about how she works with users and beamline scientists and how it connects to her past lives as a researcher and undergraduate student instructor. And, learn how her hobbies still allow her to experiment. Read more »

Haris Mahic, Accelerator and Floor Operator

As an accelerator and floor operator, Haris’s work takes him all over the ALS. But, it is his photography hobby that has left an indelible mark on the ALS homepage. Let’s take a closer look at how he helps keep the ALS running and what brought him here in the first place. Read more »

Simon Leemann, Accelerator Operations & Development Deputy

Simon Leemann’s job is to make sure the accelerator runs well—work that has taken him all over the world. Find out which languages he’s learned to speak as well as what gives him hope for the future. Read more »

Doug Bashaw, Electronics Engineering Technical Supervisor

As the leader of the Social Activities Task Force, Doug Bashaw helps make the ALS a more fun place to work. Find out how he went from a gunner’s mate in the U.S. Navy to the electronics team here, making the ALS a safer place to work, too. Read more »

Kristin Carrillo, Senior Material Specialist

Kristin Carrillo’s many tasks around the ALS may be a divergence from her degree in psychology and her previous life as a softball player, but the connecting thread is the relationships she’s developed with the people around her. Find out more about her work as a material specialist and how she supports the scientific mission of the ALS. Read more »

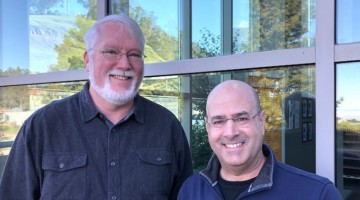

Mike Martin and Ken Goldberg, Photon Science Group Leads

Mike Martin, Photon Science Operations lead, and Ken Goldberg, Photon Science Development lead, have more in common than growing up in the Bay Area and loving physics. Together, their groups enable the current and future science of the ALS. Read more »

Inna Vishik, 2023 Users’ Executive Committee Chair

Inna Vishik began using synchrotrons in graduate school and conducts even more synchrotron research as a professor. As chair of the UEC, she is working to enhance accessibility to this facility—and has suggestions for fun things to do after beamtime, too! Read more »

- 1

- 2

- 3

- …

- 11

- Next Page »